Tradition Reinvented for Sustainable Coating Materials

Published in “RSC Sustain.” (Online Publication, March 25, 2024) and granted the back cover of “RSC Sustain. 2024, 2”

Senior Lect. Pincella, F.; Prof. Nakamura, M.

(Division of Synthetic Organotransformation,

International Research Center for Elements Science)

Dr. Ikenaga, M.; Dr. Tachibana, Y.

(Kyoto Municipal Institute of Industrial Technology and Culture)

Senior Lect. Ohta, Y.

(Center for Food Science and Wellness, Gunma University)

When we hold in our hands a smooth and lightweight cup of miso soup, we often fail to appreciate the chemistry behind the traditional wooden cup, a daily household item that is made durable, impermeable and esthetically pleasing thanks to the application of lacquer. Urushi, or Japanese lacquer, is a well-known traditional coating and adhesive material originating from the sap of the Toxicodendum vernicifluum. Despite its long history and renewable nature, which already make urushi a good model for a sustainable society, the widespread use of natural urushi is hampered by its price and reliance on a dwindling number of experts and artisans for its collection and processing. For the above reasons, our group together with collaborators from the Kyoto Municipal Institute of Industrial Technology and Culture and Gunma University, have developed a new method to obtain a synthetic urushiol (main component of urushi) analogue starting from two renewable sources: lignin from wood and fatty acids from vegetable oils. The aromatic unit of urushiol was obtained from lignin by enzymatic degradation. The polyunsaturated side chain, obtained from linolenic acid, was then introduced to the wood-derived phenylpropanoid unit. A 5-step reaction created either guayacil-type or syringil-type synthetic urushiols, depending on the nature of the lignin-derived aromatic unit. These analogues have then been characterized before and after enzymatic polymerization, to determine whether the obtained synthetic urushi film mimics the properties of natural urushi. We have finally proven that the mechanical properties and hardening process of the synthetic urushi resemble those of its natural counterpart. In summary, we have developed a new artificial urushi through enzymatic and chemical transformations of renewable resources. This novel synthetic urushi can overcome some of the limitations of natural urushi and shows a high potential as a new sustainable coating material.

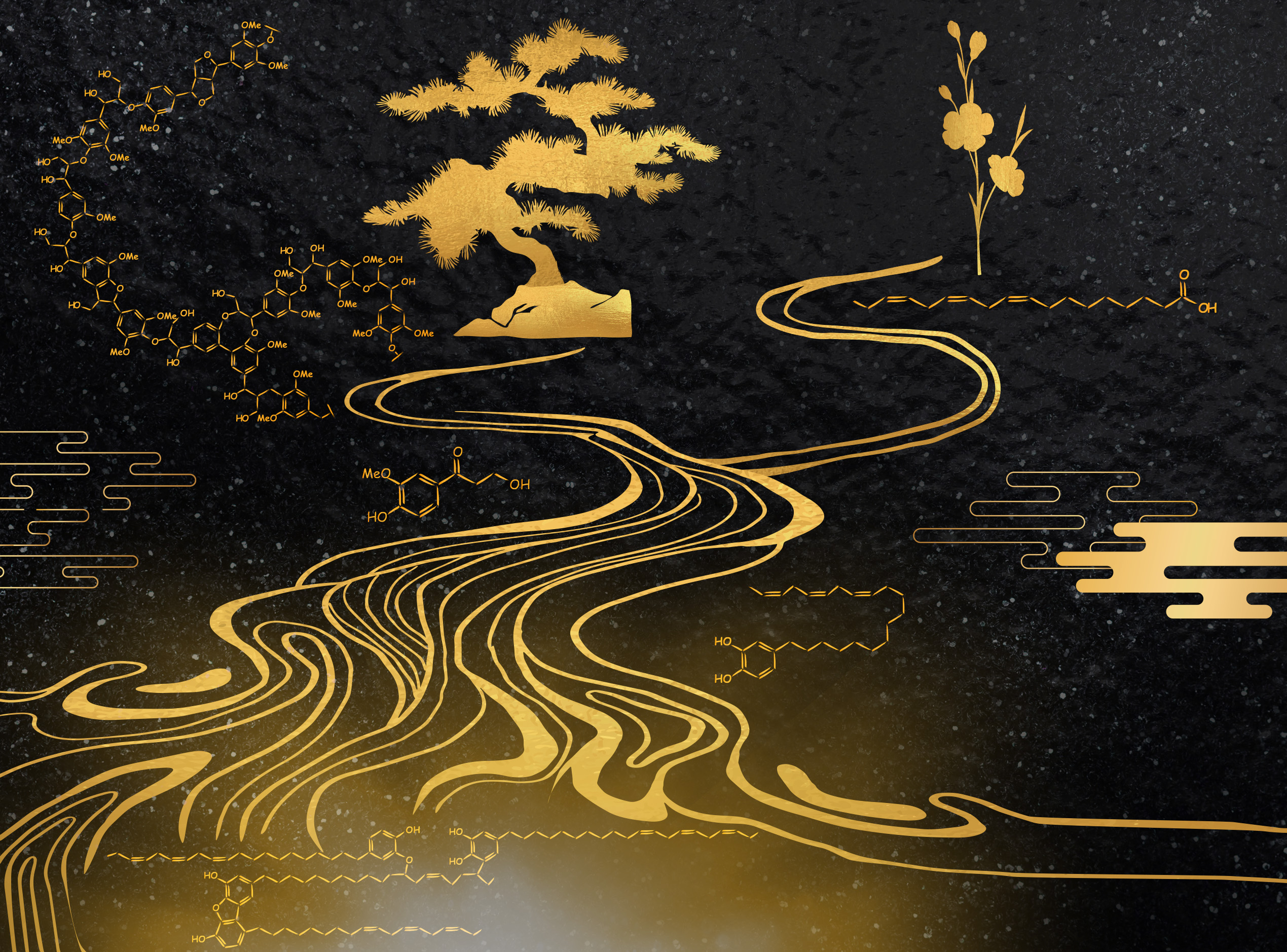

Figure : The phenylpropanoid unit from the lignin stream is coupled with the linolenic acid flowing

from the vegetable oil stream to give a synthetic urushiol from purely renewable resources.

A new durable coating film is then obtained from the polymerization of the novel urushiol analogue.

Back cover of “RSC Sustainability, 2024, 2.”

Institute for Chemical Research, Kyoto University

Institute for Chemical Research, Kyoto University International Joint Usage Research Center

International Joint Usage Research Center