Associate Professor TAKAHASHI, M., and research group“Photo-induced Formation of Wrinkled Microstructures with Long-range Order in Thin Oxide Films” (Published on web in 26 Nov 2007)

|

Associate Professor TAKAHASHI, Masahide and his research group “Photo-induced Formation of Wrinkled Microstructures with Long-range Order in Thin Oxide Films” Published in Advance Materials, 26 November 2007. |

||||

| Prof. Takahashi of Institute for Chemical Research and his collaborator at University of Sassari (Italy) and Istituto Nazionale di Fisica Nucleare (Italy) have found that the oxide films with long-range ordered structures are fabricated through self-organization processes triggered by light illumination. Periodic structures in sub-micrometer range are widely used to realize optical information processing and optical sensors, which are extensively researched as “Photonics structured films”. These photonic structured films are generally fabricated by using semiconductor processing techniques, such as photolithography. It is required to establish easy and facile ways to fabricate the photonic structured films because the semiconductor processes are usually complex and requires skill. |

Associate Professor Takahashi, M.(Left), and Mr Uemura, K.(Right) |

|||

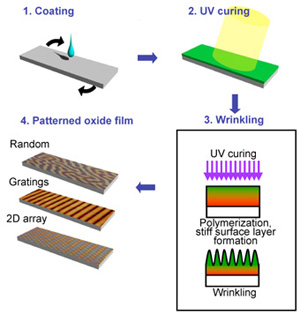

Figure 1. Schematic illustration of spontaneous formation of wrinkled patterns. 1. A hybrid acrylamide-titania film is deposited via spin-coating. 2. UV curing is applied to the film. 3. The formation of a stiff surface layer induces wrinkling on the films. 4. Thin oxide film with different wrinkled patterned structures are obtained by firing. |

Formation of ordered microstructures via spontaneous organization is in principle one of the simplest routes to produce controlled patterns in thin films. Here they show that patterned structures of oxide materials are indeed obtained through controlled processing of sol-gel films. We can induce wrinkling, through UV curing, in hybrid organic-inorganic films containing acrylamide monomers and titania precursors. We have successfully controlled the wrinkling process by slowing the evaporation of the solvents to obtain a wet and soft film even several hours after deposition. The faster polymerization of the film surface generates a buckling effect to create patterns in the films. The removal of the organic polymer by thermal treatment leaves titania microstructures having long-range order. This method of producing micropatterned structures can find several applications in photonics. | |||

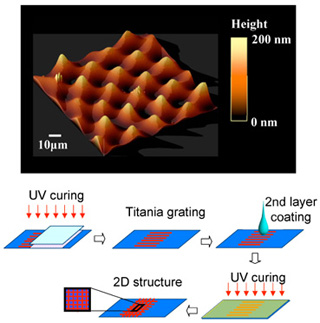

| The process of wrinkled surface structure formation (Figure 1) gives structures that spontaneously organize into different patterns at the end of the process. The buckling effect due to the hard surface is isotropic thereby giving unorientated wrinkles with just a local order, as usually observed. However, the anisotropic contraction of the film at the edges of the substrate produces highly ordered/orientated micropatterns as shown in Figure 2. The novel point of the present method is that the formation of the periodic wrinkled patterns is triggered by the UV illumination of sol-gel coatings. Therefore, we can obtain surface relief structures at the desired part of the substrate by localized illumination. In addition, the present method can be used for a variety of oxide materials which could be obtained by typical sol-gel processing. The chemical design of the coating system was carried out through collaborative work with Italian researchers on the time resolved infrared spectroscopy. |  Figure 2. AFM image of 2D dot array of TiO2 fabricated by wrinkling. First layer was fabricated by edge enhancement effect, and the second layer was deposited on the ordered first layer. All the process was carried out with pattern free substrates and homogeneous illumination of UV lamp. |

|||

|

This result has been published in Advance Materials in 26 November, 2007. This paper was judged to be very important and very urgent by editors and referees and has been featured in the “Advances in advance” section. | |||

Institute for Chemical Research, Kyoto University

Institute for Chemical Research, Kyoto University International Joint Usage Research Center

International Joint Usage Research Center